Demand Forecasting in Transport Networks: Why Most Logistics Companies Still Rely on Guesswork — and How Syntask Brings Predictive Clarity

Demand forecasting is one of the most strategic functions in logistics. It influences fleet planning, workforce allocation, pricing, procurement, customer commitments, and warehouse operations. Yet surprisingly, many logistics companies still rely on manual estimates, outdated spreadsheets, or incomplete historical data to forecast demand.

As a result:

- capacity is misaligned

- vehicles run empty or overloaded

- staff allocation becomes inefficient

- service quality fluctuates

- cost forecasts break down

- strategic decisions lose accuracy

The challenge is not that logistics companies lack data — the real challenge is converting fragmented operational data into reliable demand signals. Syntask solves this by offering a predictive forecasting engine designed specifically for freight, distribution, and transport networks.

Why Demand Forecasting Fails in Logistics

Even with tons of data available, logistics networks face unique forecasting obstacles.

1. Highly Volatile Demand Patterns

Transport demand fluctuates due to:

- seasonal peaks

- regional holidays

- commodity cycles

- promotional activities

- weather changes

- global events

- customer behavior shifts

Traditional forecasting tools struggle to integrate these variables consistently.

2. Fragmented Data Sources

Different teams record demand drivers in different systems:

- TMS order history

- customer forecasts

- sales pipelines

- WMS outbound data

- ERP records

- manual spreadsheets

Without a unified view, any forecasting model becomes unreliable.

3. Lack of Predictive Features in Traditional BI Tools

Power BI, Tableau, and Oracle BI can visualize historical patterns, but they are not designed to:

- detect future patterns

- understand seasonality

- incorporate operational variables

- model capacity constraints

- simulate multiple demand scenarios

Forecasting requires more than charts — it needs underlying data logic built for logistics.

4. Manual Calculations Reduce Accuracy

Spreadsheets often misrepresent demand due to:

- formula errors

- missing data

- inconsistent date recording

- outdated files

- subjective assumptions

This leads to poor planning decisions.

Syntask removes the manual burden and replaces it with automated predictive intelligence.

The Real Impact of Poor Forecasting

When forecasting is unreliable, logistics companies face several challenges:

• Under-allocation of fleet capacity

Demand exceeds available assets, creating service failures.

• Over-allocation

Too many vehicles or drivers are planned, creating unnecessary cost.

• Poor route planning

Mismatches between demand and location cause inefficient routes.

• Inventory misalignment

Products may overstay in warehouses or run out unexpectedly.

• Reduced profitability

Costs rise when operational capacity is not synchronized with demand. Forecasting is not optional — it is a foundation of logistics strategy.

How Syntask Enables Predictive Forecasting in Minutes

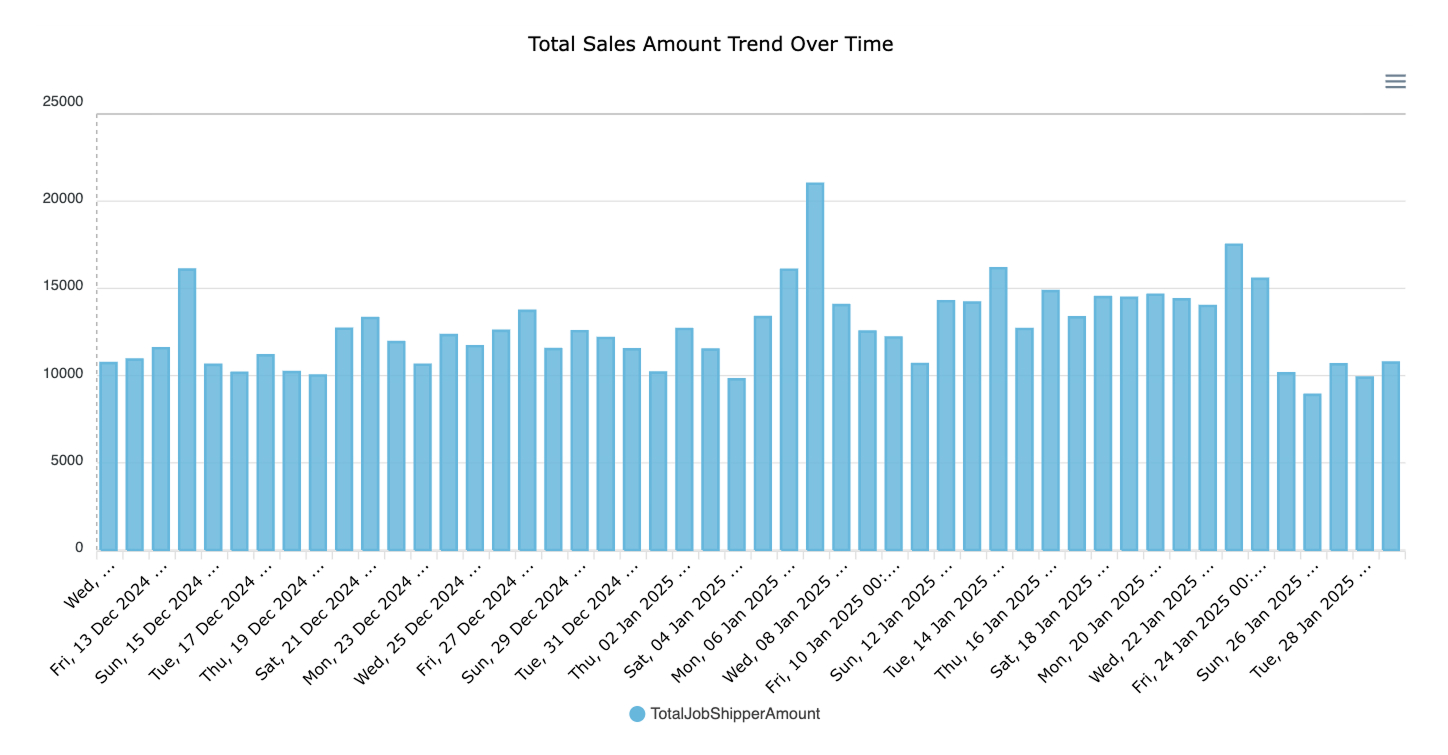

Syntask’s demand forecasting engine is created specifically for transport networks, combining historical operational data with behavior patterns. Companies can upload Excel-based order history or integrate TMS/WMS data via API for deeper forecasting capability.

1. Automated Data Normalization and Pattern Recognition

Syntask identifies:

- seasonality

- day-of-week patterns

- month-to-month volatility

- order clusters

- regional variations

- customer-specific behavior

This creates a forecasting model grounded in actual logistics behavior — not guesswork.

2. Multi-Level Forecasting

Syntask generates forecasts for:

- customers

- product groups

- regions

- transport lanes

- vehicle classes

- time periods

This allows teams to zoom in or out depending on planning need.

3. Capacity-Aware Forecasting

Unlike generic BI tools, Syntask understands:

- fleet limits

- warehouse throughput

- driver availability

- loading constraints

- shift structures

Forecasts reflect operational reality, not theoretical numbers.

4. Scenario Simulation

Syntask allows teams to simulate:

- demand spikes

- seasonal peaks

- customer growth

- reduced capacity

- market disruptions

These simulations help managers anticipate challenges and plan proactively.

5. Real-Time Forecast Updates via API

When connected to live operational systems, Syntask adjusts forecasts based on:

- current demand

- new order entries

- cancellation patterns

- traffic conditions

- regional events

This gives companies near-real-time demand visibility.

6. Chat Agent for Predictive Insights

Users can ask:

- “What is expected demand next week?”

- “Which customer will increase volume next month?”

- “Show me seasonal patterns for refrigerated shipments.”

Syntask provides clear explanations and forecast charts instantly.

Measurable Benefits for Logistics Networks

Companies using Syntask achieve:

• Up to 30–50% improvement in forecasting accuracy

Leading to better planning and cost control.

• Lower empty-km and higher fleet utilization

Capacity aligned with true demand.

• More predictable labor planning

Workforce matches real workload.

• Better customer commitment accuracy

Promises match operational reality.

• Reduced operational cost

Less overtime, fewer delays, more consistent dispatching. Demand forecasting becomes a reliable decision tool rather than a guesswork exercise.

Conclusion

Accurate forecasting is essential for any logistics organization aiming to scale efficiently. Yet traditional tools and manual spreadsheets fail to capture the dynamic nature of transport networks.

Syntask offers a predictive forecasting engine built specifically for the logistics domain. By combining historical trends, real-time variables, and operational constraints, Syntask provides accurate forecasts with minimal manual input.

This helps logistics organizations plan smarter, reduce cost, improve service reliability, and strengthen their competitive position.