Operational Health Score: How Logistics Companies Can Finally See the True State of Their Daily Operations

Most logistics leaders ask the same fundamental question every day:

“How healthy are our operations right now?”

Surprisingly, very few companies can answer this question with confidence.

- Operations might feel busy.

- Teams might seem productive.

- Delivery performance might appear stable.

But without an objective, data-driven operational health score, logistics companies operate in the dark — relying on fragmented dashboards, gut feelings, and outdated reports.

An operational health score provides the visibility logistics teams desperately need. It consolidates all key performance indicators into one simple, real-time view and shows whether the operation is performing well, facing risk, or moving toward a bottleneck.

Syntask provides this clarity instantly.

Why Operational Health Is Hard to Measure

Logistics operations consist of multiple interconnected workflows:

- fleet movement

- delivery performance

- warehouse flow

- route efficiency

- exception handling

- cost behavior

- subcontractor performance

- capacity utilization

Traditional BI setups split these metrics into separate dashboards, making it nearly impossible to see the full picture.

1. KPIs Are Fragmented Across Systems

Different systems track different indicators:

- TMS tracks routes

- WMS tracks warehouse processes

- telematics tracks vehicles

- ERP tracks cost

- manual reports track driver notes

No single source shows overall operational health.

2. KPIs Have Different Definitions Across Teams

Operations measure:

- on-time performance

Finance measures:

- cost per trip

Fleet teams measure:

- empty km

Warehouse teams measure:

- throughput

When definitions are not aligned, results conflict.

3. Dashboards Do Not Provide a Unified View

Even with three or four dashboards, managers still ask:

- “Are we performing well today?”

- “Where is the risk?”

- “Which area needs attention first?”

Traditional BI tools cannot merge KPIs into one unified score.

4. Manual Monitoring Is Not Sustainable

Teams spend hours reviewing metrics, blending spreadsheets, or validating numbers.

This slows decision-making and increases error risk.

Syntask solves this by building an automated operational health scoring model specifically for logistics operations.

The Impact of Not Having an Operational Health Score

Without a clear daily health score, companies experience:

• Slow reaction to operational issues

Problems escalate before anyone notices.

• Declining service reliability

Late detection of issues leads to customer dissatisfaction.

• Inconsistent performance across regions

Some teams operate well while others lag behind unnoticed.

• High operational cost

Inefficiencies remain hidden.

• Stress on management and teams

Without clarity, every day feels unpredictable. A unified operational health score creates structure, visibility, and stability.

How Syntask Delivers Operational Health Scoring

Syntask gathers all operational metrics, evaluates their significance, and produces a daily health performance score — similar to how a medical report summarizes the condition of a patient.

This gives logistics leaders a single source of truth.

1. Automated KPI Normalization and Weighting

Syntask automatically normalizes KPIs to account for:

- volume differences

- regional variations

- seasonal effects

- operational sensitivity

Each KPI is weighted according to its impact on operational performance.

Examples:

- route efficiency has a stronger weight than fuel deviation

- exception rate has higher impact than individual delays

- empty-km ratio affects cost and must be prioritized

This creates objective scoring.

2. Operational Categories Included in the Score

The Syntask health score evaluates:

• Delivery Performance

On-time vs delayed shipments.

• Route Efficiency

Travel time, deviation rate, idle patterns.

• Fleet Utilization

Empty km, load ratio, time utilization.

• Warehouse Flow

Throughput, picking performance, inbound/outbound timing.

• Partner Reliability

Subcontractor performance consistency.

• Cost Behavior

Cost-per-km, lane profitability, cost deviations.

• Exception Frequency

Delivery failures, reattempts, disruptions.

• Capacity Alignment

Demand vs capacity readiness. Instead of reviewing 20+ dashboards, leaders view one score.

3. Traffic Light Status for Instant Interpretation

Syntask presents operational health with a simple, intuitive view:

- Green → operations are stable

- Yellow → attention needed

- Red → immediate action required

This eliminates confusion and enables faster decision-making.

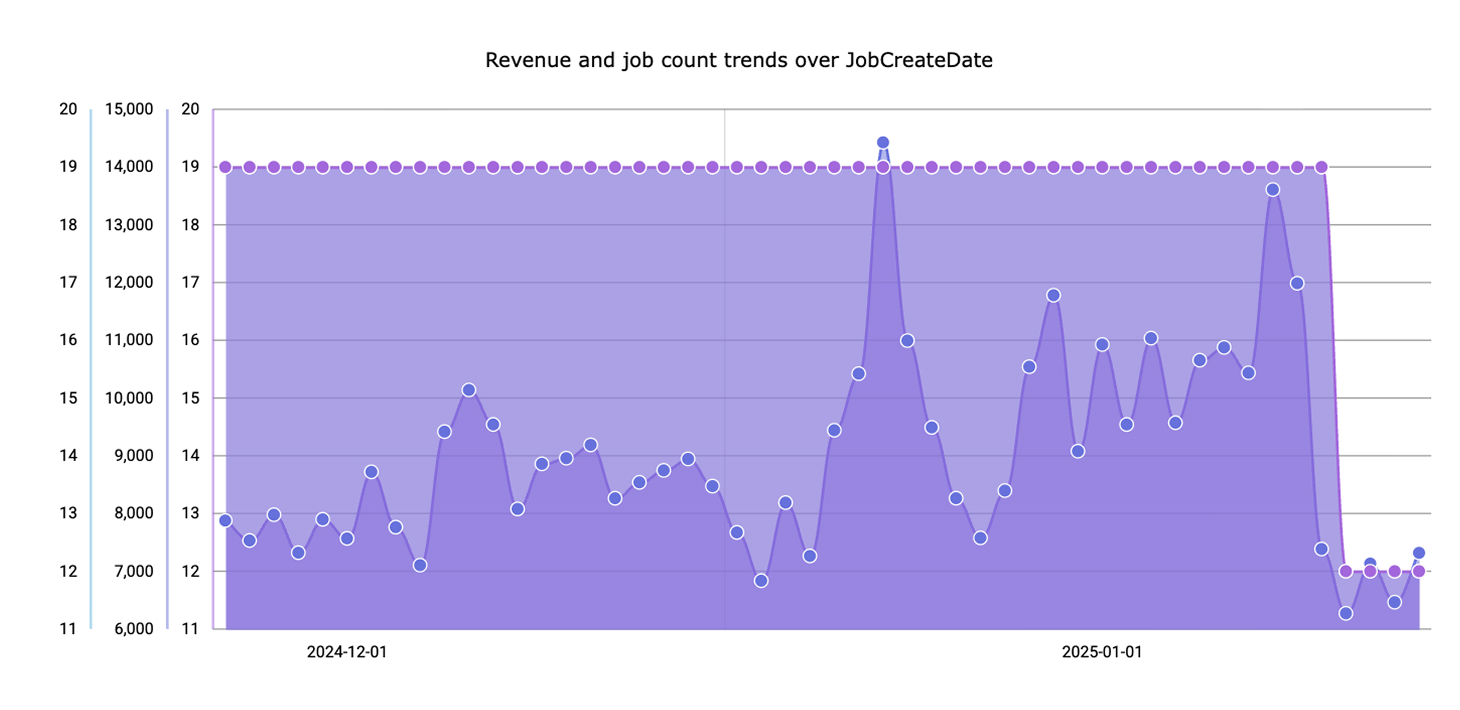

4. Automated Trend Detection

Syntask identifies:

- performance drops

- developing risks

- repeating patterns

- improvement opportunities

For example:

- “Exception rate increased 12% this week — caused by partner A.”

- “Fleet utilization dropped due to imbalanced regional demand.”

- “Warehouse outbound congestion detected between 2 PM and 4 PM.”

Trends become visible instantly.

5. Chat Agent for Root Cause Analysis

Users can ask:

- “Why is today’s score lower than yesterday?”

- “Which region is causing the drop?”

- “Show me which KPI impacted the score most.”

Syntask responds with:

- explanations

- breakdowns

- visuals

- recommended actions

This replaces hours of manual investigation.

Measurable Benefits for Logistics Teams

With Syntask’s operational health score, companies achieve:

• Faster response to operational issues

Problems are detected early.

• Stronger service reliability

Performance becomes predictable.

• Reduced operational cost

Inefficiencies become visible.

• Better cross-team coordination

All departments work from the same truth.

• Confidence in scale-up decisions

Leaders understand where the operation stands — daily. The health score becomes the operational heartbeat of the company.

Conclusion

Operational health is the defining factor of logistics performance. Yet most companies do not have an objective, consolidated way to monitor it. Syntask solves this by providing an automated operational health scoring engine that evaluates every part of the logistics workflow — fleet, warehouse, delivery, cost, partners, and demand — and presents it in one unified view. This enables logistics teams to detect problems early, allocate resources effectively, and operate with confidence.

Syntask transforms daily logistics management into a structured, clear, and predictable process.